SeatsSeats - Covers and Refurbishment

Our large workshop facilities in Hertfordshire, UK allow us to completely overhaul passenger seat ship sets from assembly to repair. Working to maintenance data and approved drawings, we are able to refurbish a full range of seats and can also incorporate customised features.

Your seats will be brought back to life with our expertly sewn seat covers. Our seat covers fit perfectly snugly and smoothly without the folds and ridges often found with poor craftsmanship.

Seat covers are stitched in fabric or leather of customers’ choice or to branding requirements. All covers are released with approved certification and burns documentation.

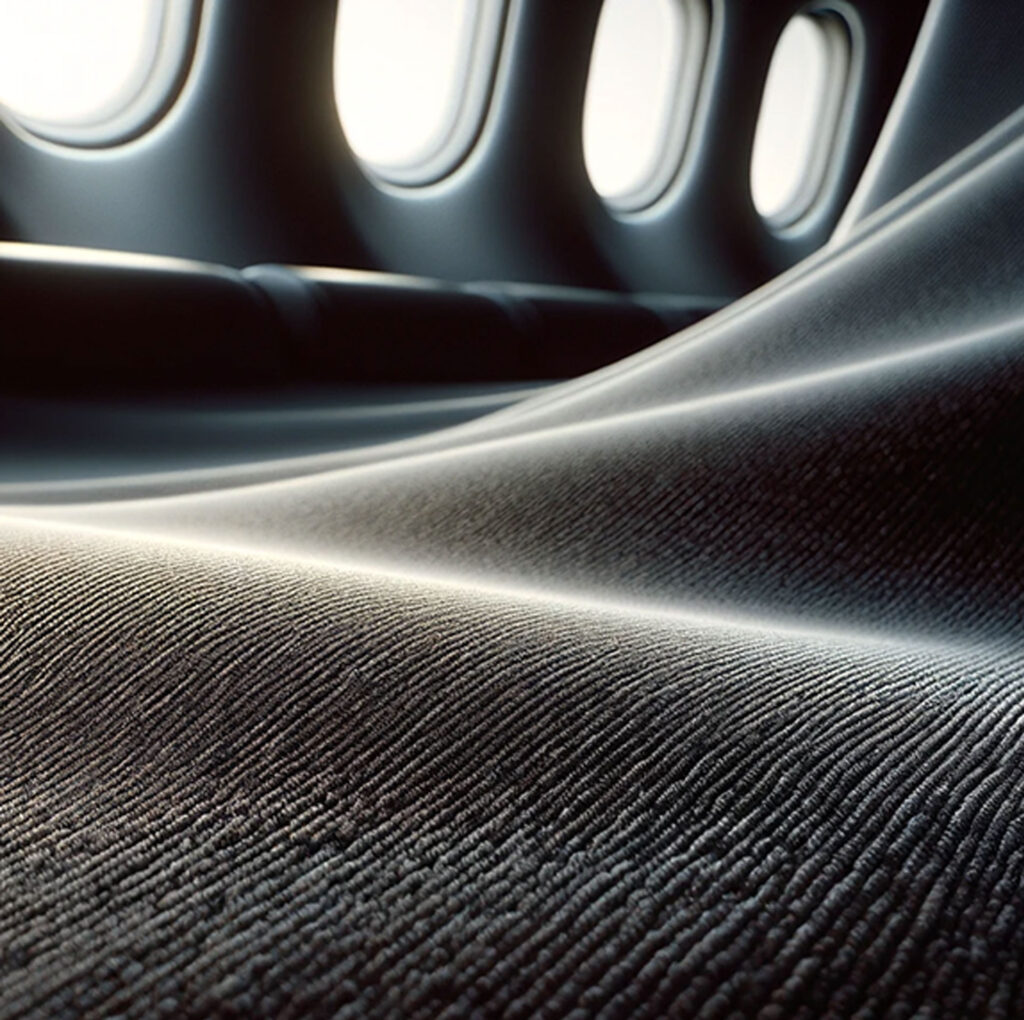

CarpetsCarpet kits

Our bespoke cabin carpeting solutions are designed to enhance the aesthetic appeal and passenger comfort of any aircraft interior.

We can supply a range of aircraft carpets to meet customer specific requirements.

Working with all major suppliers, we provide the very best in carpet solutions, offering a fast response from our vast stock, with the ability to produce and install a ship set within 48 hours.

From the initial design concept to installation, our team works closely with clients to ensure a seamless fit and impeccable finish.

We also understand the importance of safety and compliance in the aviation industry, which is why all our cabin carpets meet stringent flame-retardancy standards and aviation regulations.

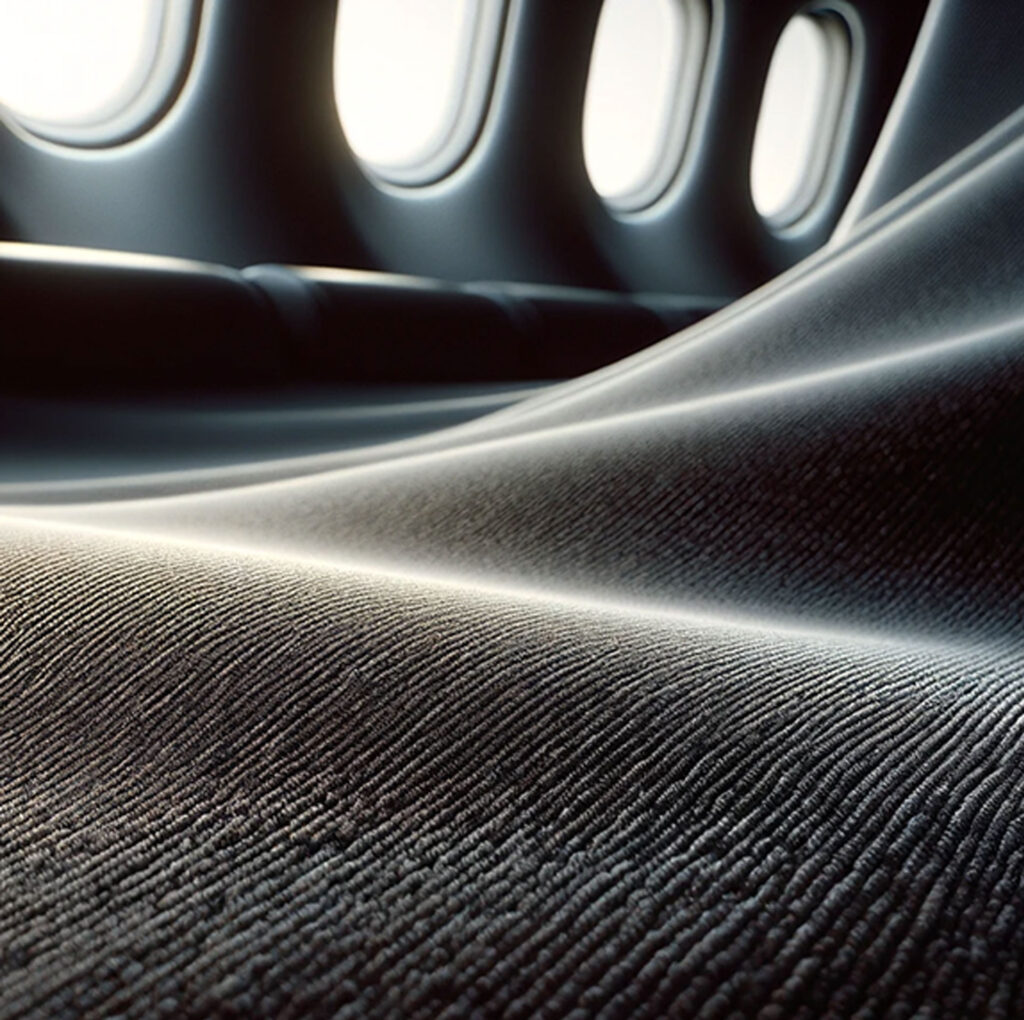

CarpetsCarpet kits

Our bespoke cabin carpeting solutions are designed to enhance the aesthetic appeal and passenger comfort of any aircraft interior.

We can supply a range of aircraft carpets to meet customer specific requirements.

Working with all major suppliers, we provide the very best in carpet solutions, offering a fast response from our vast stock, with the ability to produce and install a ship set within 48 hours.

From the initial design concept to installation, our team works closely with clients to ensure a seamless fit and impeccable finish.

We also understand the importance of safety and compliance in the aviation industry, which is why all our cabin carpets meet stringent flame-retardancy standards and aviation regulations.

UpholsteryUpholstery

We have an extensive aircraft curtain manufacturing capability. Individually designed to meet customer needs, all styles and sizes of curtains can be manufactured to requirement and produced with very short lead times. We offer either steam pressed or stitched versions. Advice and recommendations given on customer request. Our skilled upholsterers create:

- Cabin curtains

- Sound-proof curtains (crew rest)

- Literature Pockets

- Antimacassar

We also offer design and manufacture of the curtain track and structural attachments, including the modification paperwork.

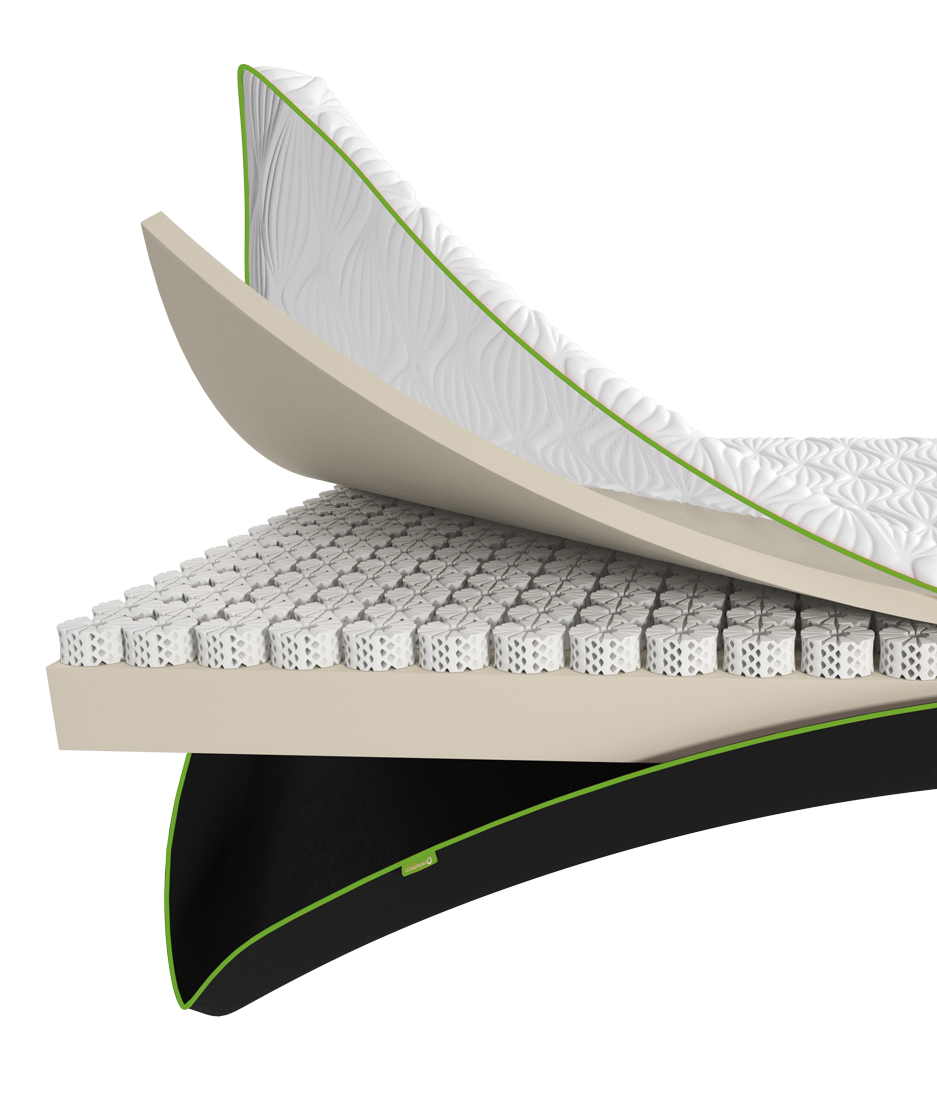

MattressesOctaspring, best new comfort innovation in aerospace

Powered by multi-award winning Octaspring technology, the topper delivers 3-dimensional support, through the ability to perfectly adapt to every inch of your body, cradling it and providing a new level of comfort.

50% less material is used in production of every Octaspring spring, Octaspring technology is lighter - creating less CO2, when manufacturing cabin crew mattresses. Weight savings of up to 150g per mattress can be achieved.

The patented OCTAvent air system makes your cabin crew mattress naturally 8x more breathable, which cools your bed temperature by 3°C. It provides a constant airflow – body movements push warm, humid air out of the specially designed sides of the Octaspring springs, drawing fresh air back in.

Depending on the design of the set currently on the A/C the mattresses are on average 20 to 30% cheaper compared to OEM.

The mattress uses less material than other market OEM mattresses, with high breathability and constant airflow. This makes for more comfort and a lower overall temperature for sleeping.

Thanks to the collaboration with Manifattura Testori, we can now offer 100% recycled and recyclable covers to complete the assembly of the mattresses. These are lightweight, saving approximately 9kg per aircraft.

The mattress technology is patented, so cannot be duplicated by other crew mattress manufacturers. The first year of dry cleaning is completely free of charge.

We can also offer anti bed bugs treatment, which guarantees 99% efficacy.

We use 50% less material is used in the production of every Octaspring spring, which results in up to 31% less raw material used in every mattress.

Weight savings of up to 150g in Economy and up to 800g in Business Class seats can result in up to 32 tons of weight savings per plane per year.

Our calculations have found that weight savings through Octaspring technology can reduce fuel consumption by up to 14,825L per aircraft per year

Weight savings created by Octaspring technology have the potential to deliver 46tons lower CO2 emissions per plane per year.